When the wax contours have been completed, the dentures are removed from the articulator mountings, invested in a flask, and the wax replaced with polymerized acrylic resin. This program illustrates the injection molding method.

Complete Dentures – Denture Processing — Course Transcript

- 1. 27. Denture Processing John Beumer III, DDS, MS Division of Advanced Prosthodontics, Biomaterials and Hospital Dentistry UCLA School of Dentistry This program of instruction is protected by copyright ©. No portion of this program of instruction may be reproduced, recorded or transferred by any means electronic, digital, photographic, mechanical etc., or by any information storage or retrieval system, without prior permission.

- 2. Preparing Dentures for Processing Injection molding We recommend the SR Ivocap System Less distortion during processing Minimal pin opening Result: Laboratory remount much simplified .

- 3. Preparing Dentures for Processing Injection molding We recommend the SR Ivocap System Less distortion during processing Minimal pin opening

- 4. When festooning is completed . . . . . . Seal the periphery of the denture flange to the inner edge of the land of the cast. Flasking

- 5. After soaking the master casts and mountings in water for a few minutes, gently remove the casts from the mountings. Both dentures are sealed onto their respective casts Flasking

- 6. Neither the master cast nor the mounting has been damaged. Following processing into heat cured acrylic resin the denture and casts can be precisely reattached to the mountings . Flasking

- 7. Denture flasks . Note that the trial dentures and the master casts fit easily within the flasks. The denture flasks are partially filled with stone and the casts are then positioned within the flask so that the land of the cast and the plaster is at about the same level as the edge of the flask. The injection funnel is positioned after the stone has set. Flasking

- 8. The injection channels must be 3-5 mm in diameter. For the maxilla one channel is sufficient. For the mandible two are required. Flasking An appropriate separating medium is applied to the surface of the stone.

- 9. Note that the stone application is below the level of the upper half of the flask. A thin layer of improved dental stone is applied to the surface of the trial denture. Flasking

- 10. The flask is filled to the brim with stone and the lid positioned as shown. Flasking

- 11. The wax and the record bases have been removed by hot water washes. The denture teeth are imbedded in one side of the flask and the master casts are imbedded in the other side. Boil Out After drying the stone, both sides are covered by a tin foil substitute. Avoid coating the denture teeth with the tin foil substitute.

- 12. Capsule Preparation Contents of the capsule: 20 grams polymer, 30 ml of monomer. Remove the monomer capsule and break it open by twisting off the sealed end. Open the capsule and pour the monomer into it.

- 13. Mount the capsule in the Cap Vibrator, attach the securing thong, and mix for 5 minutes at room temperature. Mixing the Resin When properly mixed a ball of resin forms within the capsule as shown.

- 14. Remove the empty monomer container, place the capsule on the capsule plunger and press the contents upwards. There should be no air between the plunger and the contents. Preparing the Resin for Injection

- 15. Assemble and Clamp the Flask Carefully bring the two halves of the flasks together and and slide them into the clamping frame. Push the ratchet and clamp lever to the right (arrow) while applying the recommended pressure to the clamping frame.

- 16. Inserting the SR Ivocap Capsules Remove the cover from the capsule and fully insert the capsule into the flask .

- 17. Mounting the Pressure Apparatus Fully extend the plunger of the pressure apparatus, by pulling the piston rod when the compressed air locking valve is open. Place the SR Ivocap pressure apparatus on the flask, lift the safety loop, and press the plunger into the capsule until the vise shanks are correctly positioned on the flask. Then pull down the safety loop until it snaps into place.

- 18. Polymerization of the Acrylic Resin Place the SR Ivocap assembly in the polymerization bath as shown. The surface of the water should be covered by plastic floaters in order to prevent unnecessary loss of heat. The water should boil during the entire cycle. The water level must reach the red mark on the clamping frame but not exceed this level. Polymerization takes 35 minutes .

- 19. Polymerization of the Acrylic Resin The processed dentures are removed from the flasks taking special care to avoid injury to the master casts.

Restoration of Posterior Quadrants and Treatment Planning

Restoration of Posterior Quadrants and Treatment Planning

Single Tooth Defects in Posterior Quadrants

Single Tooth Defects in Posterior Quadrants

Prosthodontic Procedures and Complications

Prosthodontic Procedures and Complications

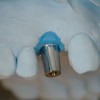

Cement Retention vs Screw Retention

Cement Retention vs Screw Retention